Activities we develop

FLOW INSURANCE IN WELLS AND DEVELOPMENT OF OIL AND GAS FIELDS

EVALUATION OF DEPOSITS AND PRODUCTIVITY

Integrated Field Studies and Model Development

Data validation and scope of studies, construction of the reservoir model, numerical simulation of reservoirs.

Reservoir Production Behavior Assessment

By applying principles and techniques of artificial production lift, by reviewing existing wells (mature fields), analysis of the decline in production and pressure, oil, gas and water production behavior, productivity index per well, efficiency of the secondary recovery process, position of the gas-oil and / or petroleum water contact, review of possible additional producer zones or intervals, location and classification of productivity zones, review of reserves.

Personnel Training

In reservoir and production engineering that allow personnel to carry out control and monitoring tasks to the production objectives.

Deposit Management

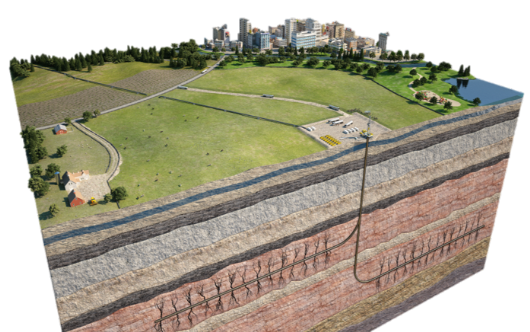

Through the selective fracturing of the rock to optimize the recovery of reserves and the control of the production of the deposit.

ENGINEERING OF PERFORATION AND DESIGN OF TERMINATION OF CONVENTIONAL AND NON-CONVENTIONAL WELLS

Visualization, Conceptualization and Definition

Of drilling projects using the Front End Loading technique for greater control of the deadlines and costs associated with drilling, repair and rehabilitation of wells, by defining control variables and TIR values. Application of standards and best practices of Cementation in Intermediate and Production holes. Technical- operational audits.

PRODUCTION ENGINEERING

Conceptual, basic and detailed engineering of oil and gas production facilities. Artificial lifting systems. Oil movement systems. Studies of hydrocarbon waste. Diagnosis and solution of operational problems: Productivity of active and inactive wells. Treatment and dehydration of crude. Oil and gas collection systems. Optimization of oil and gas production systems. Advice on water and gas injection plants. Analysis of production costs.

SECURITY, HYGIENE AND ENVIRONMENT

Advice for the adaptation of production processes to the environmental regulations of Pemex, especially in congenital waters, atmospheric emissions and toxic waste. Study and analysis of oil spills and proposals for preventive and corrective actions. Analysis for disposal and / or correction of environmental liabilities, including abandonment of wells and blinding of graves. Risk Engineering RIG PASS, WellCAP. Certification Program for Safety, Hygiene and Environment Supervisors.

STAFF TRAINING

Programming of the following courses: Operation of the deposits, attributes of the extraction systems. Mechanical pumping. Pumping through progressive cavities. Electro-submersible pumping. Plunger lift Analysis and design of mechanical pumping (calculations). Course for production operators. Srod (nabla) - software for design of mechanical pumping systems. Production simulators, nodal analysis calculation. Courses of Hygiene, Safety and Environment for Supervisors.